- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

FAF37,FAF47,FAF57,FAF67,FAF77,FAF87,FAF97,FAF107.FAF127,FAF157

HUAKE

The HUAKE F Series Gear Motor - FAF47 is a high-performance transmission solution engineered for diverse industrial needs. As a core model in HUAKE’s F Series, this FAF47 Gear Motor delivers exceptional high torque output (up to 200 N·m) and outstanding energy efficiency, making it ideal for long-term, continuous operation. Its innovative modular design allows seamless integration with various motor types and power inputs (ranging from 0.18 kW to 3 kW), ensuring flexibility across different industrial setups. Crafted by Qingdao Chinese Science Machinery Co., Ltd., a leading gear motor manufacturer, the FAF47 prioritizes reliability, durability, and cost-effectiveness, standing out as a top choice for businesses seeking stable transmission performance.

Weighing only 13 kg, the FAF47 Gear Motor features a space-saving compact design. This advantage is critical for space-constrained installations (e.g., small-scale automated production lines) where traditional bulky gear motors fail to fit—without compromising power output or operational stability. Its lightweight nature also simplifies on-site integration into existing systems, reducing labor and installation time.

With a gear ratio range of 3.81 to 128.51, the FAF47 adapts to varied speed and torque requirements across industries. Whether adjusting for slow-speed, high-torque tasks (e.g., heavy material lifting) or moderate-speed operations (e.g., conveyor belt control), this versatile gear motor eliminates the need for additional transmission components, lowering overall system costs.

Constructed with high-quality steel cast iron and premium steel, the FAF47 resists wear and tear even in harsh industrial environments. Its gears undergo high-frequency heat treatment, significantly enhancing wear resistance and extending service life. This design minimizes maintenance frequency, reducing downtime and operational costs for businesses relying on continuous production.

The modular gear motor design supports integration with AC motors, DC motors, and stepper motors, catering to diverse power input needs. This compatibility eliminates the hassle of custom adapters, allowing quick replacement or upgrade of motors without redesigning the entire transmission system.

Parameter | Value |

Model | FAF47 (F Series) |

Brand | HUAKE |

Input Power | 0.18 – 3 kW |

Gear Ratio Range | 3.81 – 128.51 |

Max Permissible Torque | 200 N·m |

Gear Unit Weight | 13 kg (mean value) |

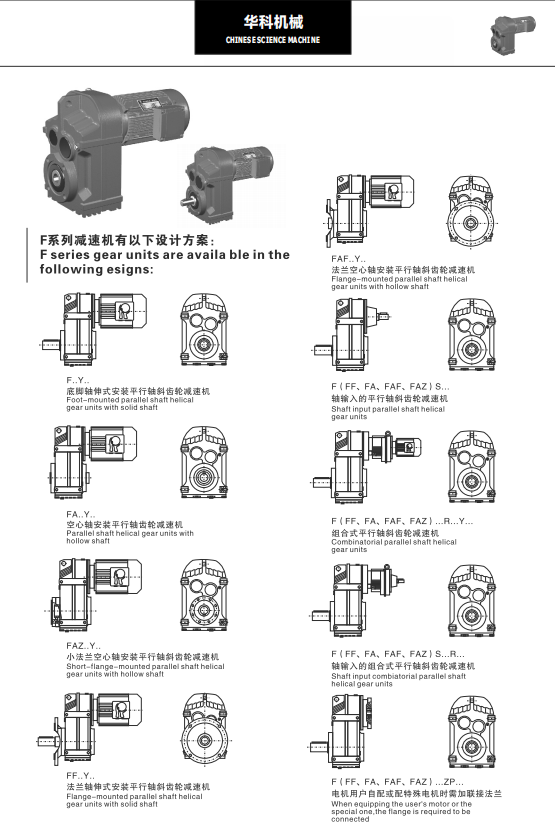

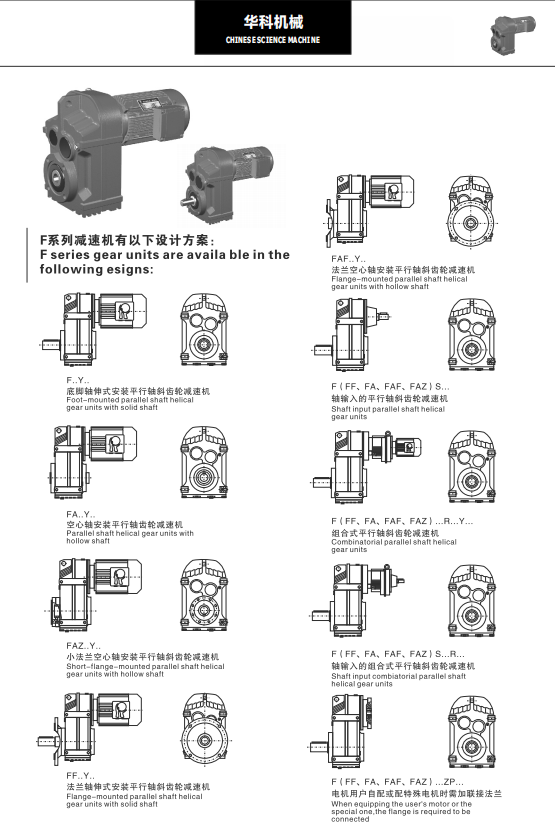

Structure Type | FAF (flange-mounted, hollow shaft) |

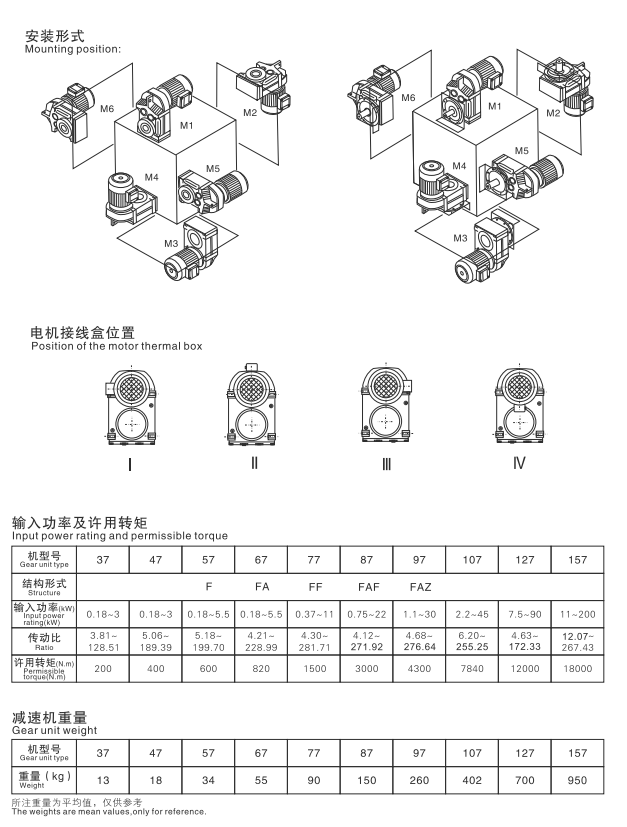

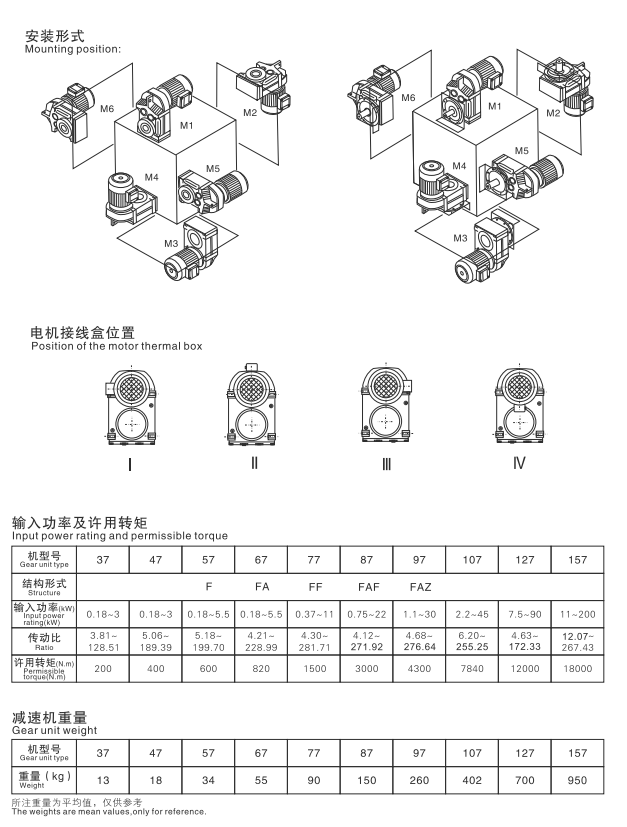

Mounting Positions | M1, M2, M3, M4, M5, M6 |

Motor Terminal Box Positions | I, IV |

Material | Steel cast iron + premium steel |

The high torque gear motor excels in material handling (e.g., forklifts, hoists), providing sufficient force to lift heavy loads (up to 200 N·m torque) while maintaining energy efficiency—critical for reducing electricity consumption during long shifts.

In manufacturing and logistics, the FAF47 drives conveyor systems (e.g., assembly line conveyors, warehouse sorting belts). Its wide gear ratio range allows precise speed control, ensuring smooth product transportation and reducing product damage risks.

For automated machinery (e.g., robotic arms, packaging machines), the FAF47’s compact design and low vibration ensure precise, stable operation. Its durability also supports 24/7 production cycles, a key demand in modern automation.

In industries like food processing and textile manufacturing, the energy-efficient gear motor reduces operational costs, while its easy maintenance minimizes production interruptions—aligning with the need for hygienic, low-downtime equipment.

It supports a wide input power range of 0.18 kW to 3 kW, compatible with most standard industrial motors.

While its steel cast iron body resists mild moisture, we recommend additional waterproofing for outdoor or humid environments to extend service life.

Yes, Qingdao Chinese Science Machinery Co., Ltd. offers customized gear motor solutions (e.g., adjusted gear ratios, special mounting brackets) to meet specific industrial needs.

Thanks to heat-treated gears and durable materials, routine maintenance (e.g., lubricant replacement) is only needed every 6–12 months under normal operation.

With proper maintenance, the FAF47 typically delivers a service life of 8–10 years, outperforming many entry-level gear motors.

The HUAKE F Series Gear Motor - FAF47 is a high-performance transmission solution engineered for diverse industrial needs. As a core model in HUAKE’s F Series, this FAF47 Gear Motor delivers exceptional high torque output (up to 200 N·m) and outstanding energy efficiency, making it ideal for long-term, continuous operation. Its innovative modular design allows seamless integration with various motor types and power inputs (ranging from 0.18 kW to 3 kW), ensuring flexibility across different industrial setups. Crafted by Qingdao Chinese Science Machinery Co., Ltd., a leading gear motor manufacturer, the FAF47 prioritizes reliability, durability, and cost-effectiveness, standing out as a top choice for businesses seeking stable transmission performance.

Weighing only 13 kg, the FAF47 Gear Motor features a space-saving compact design. This advantage is critical for space-constrained installations (e.g., small-scale automated production lines) where traditional bulky gear motors fail to fit—without compromising power output or operational stability. Its lightweight nature also simplifies on-site integration into existing systems, reducing labor and installation time.

With a gear ratio range of 3.81 to 128.51, the FAF47 adapts to varied speed and torque requirements across industries. Whether adjusting for slow-speed, high-torque tasks (e.g., heavy material lifting) or moderate-speed operations (e.g., conveyor belt control), this versatile gear motor eliminates the need for additional transmission components, lowering overall system costs.

Constructed with high-quality steel cast iron and premium steel, the FAF47 resists wear and tear even in harsh industrial environments. Its gears undergo high-frequency heat treatment, significantly enhancing wear resistance and extending service life. This design minimizes maintenance frequency, reducing downtime and operational costs for businesses relying on continuous production.

The modular gear motor design supports integration with AC motors, DC motors, and stepper motors, catering to diverse power input needs. This compatibility eliminates the hassle of custom adapters, allowing quick replacement or upgrade of motors without redesigning the entire transmission system.

Parameter | Value |

Model | FAF47 (F Series) |

Brand | HUAKE |

Input Power | 0.18 – 3 kW |

Gear Ratio Range | 3.81 – 128.51 |

Max Permissible Torque | 200 N·m |

Gear Unit Weight | 13 kg (mean value) |

Structure Type | FAF (flange-mounted, hollow shaft) |

Mounting Positions | M1, M2, M3, M4, M5, M6 |

Motor Terminal Box Positions | I, IV |

Material | Steel cast iron + premium steel |

The high torque gear motor excels in material handling (e.g., forklifts, hoists), providing sufficient force to lift heavy loads (up to 200 N·m torque) while maintaining energy efficiency—critical for reducing electricity consumption during long shifts.

In manufacturing and logistics, the FAF47 drives conveyor systems (e.g., assembly line conveyors, warehouse sorting belts). Its wide gear ratio range allows precise speed control, ensuring smooth product transportation and reducing product damage risks.

For automated machinery (e.g., robotic arms, packaging machines), the FAF47’s compact design and low vibration ensure precise, stable operation. Its durability also supports 24/7 production cycles, a key demand in modern automation.

In industries like food processing and textile manufacturing, the energy-efficient gear motor reduces operational costs, while its easy maintenance minimizes production interruptions—aligning with the need for hygienic, low-downtime equipment.

It supports a wide input power range of 0.18 kW to 3 kW, compatible with most standard industrial motors.

While its steel cast iron body resists mild moisture, we recommend additional waterproofing for outdoor or humid environments to extend service life.

Yes, Qingdao Chinese Science Machinery Co., Ltd. offers customized gear motor solutions (e.g., adjusted gear ratios, special mounting brackets) to meet specific industrial needs.

Thanks to heat-treated gears and durable materials, routine maintenance (e.g., lubricant replacement) is only needed every 6–12 months under normal operation.

With proper maintenance, the FAF47 typically delivers a service life of 8–10 years, outperforming many entry-level gear motors.