- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

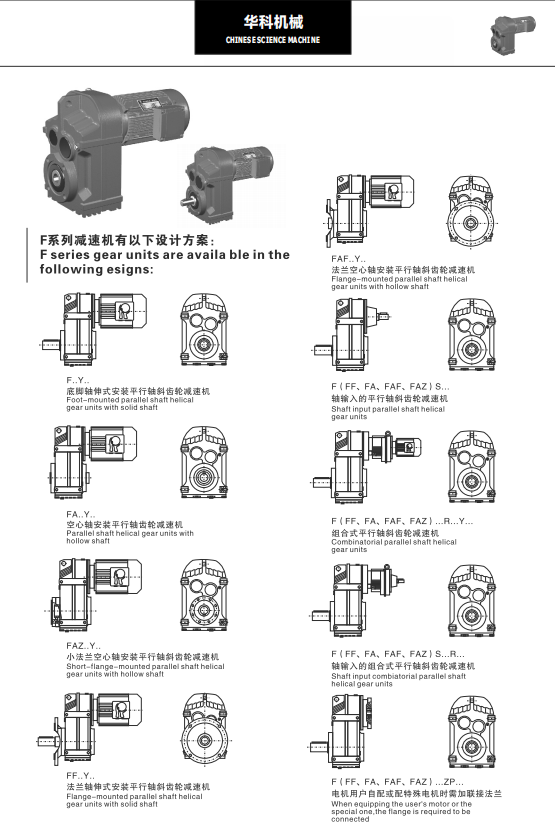

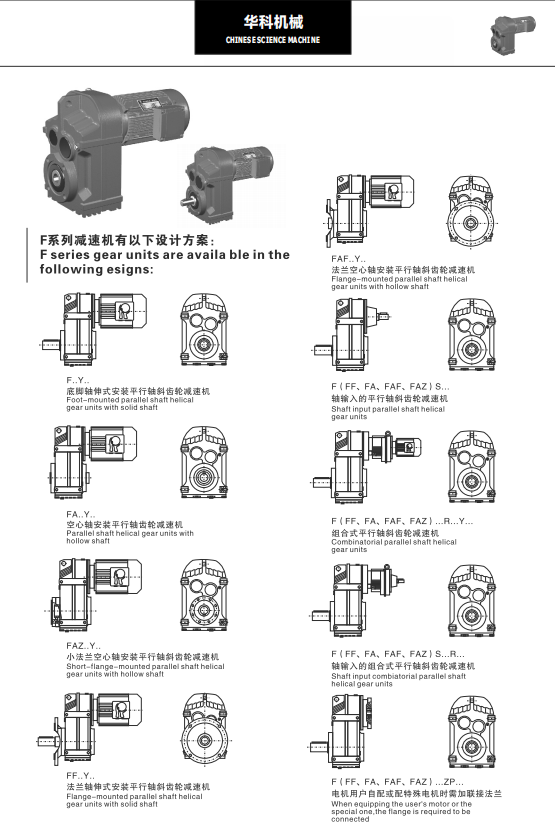

FF37,FF47,FF57,FF67,FF77,FF87,FF97,FF107.FF127,FF157

HUAKE

The F Series Parallel Shaft Helical Gear Reducer (Model FF107) is an industrial-grade drive unit engineered for heavy-duty conveying, mixing, and lifting applications.

Featuring a parallel shaft configuration, helical gear engagement, and high torque capacity, it ensures smooth power transmission with exceptional efficiency and durability.

With an input power range of 2.2–45 kW, output torque up to 7,840 N·m, and efficiency above 96%, the FF107 is the ideal choice for equipment requiring continuous, stable, and space-aligned power delivery.

High Torque Output (7,840 N·m)

Designed for heavy-duty mechanical systems demanding reliable, long-term torque performance.

Parallel Shaft Design

Ensures linear alignment between motor and driven equipment — perfect for long conveyor and material handling systems.

Wide Ratio Range (6.20–255.25)

Offers flexible speed adjustment to suit various industrial transmission requirements.

High Efficiency (≈96%)

Helical gear design reduces friction losses and provides smooth, energy-saving operation.

Strong & Rigid Construction

Heavy-duty cast iron housing with hardened alloy steel gears ensures excellent shock resistance.

Low Noise & Vibration

Precision-ground gears and optimized tooth profiles guarantee quiet, stable performance.

Easy Integration

Modular system supports IEC-standard motors, variable-frequency drives, and braking motors.

Reliable for Continuous Duty

Engineered for 24/7 operation under industrial environments with minimal maintenance needs.

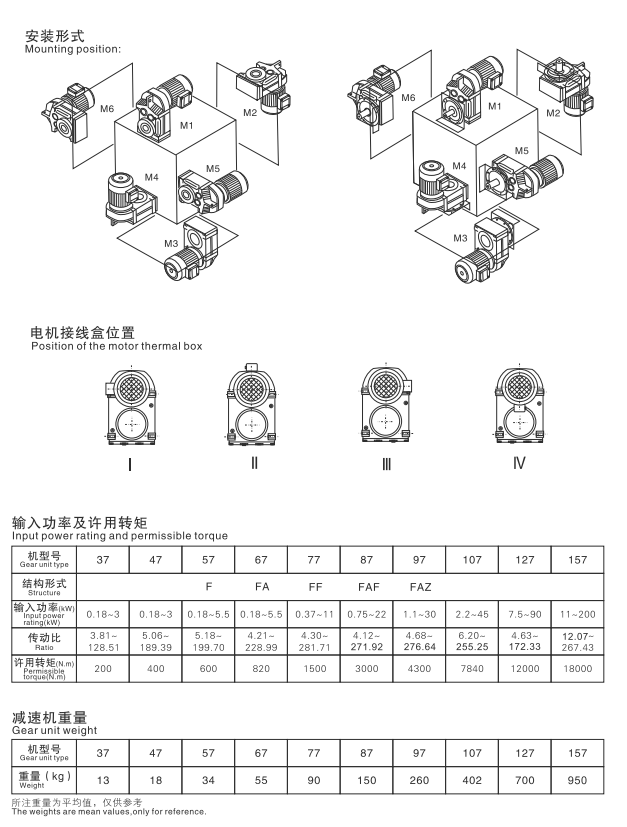

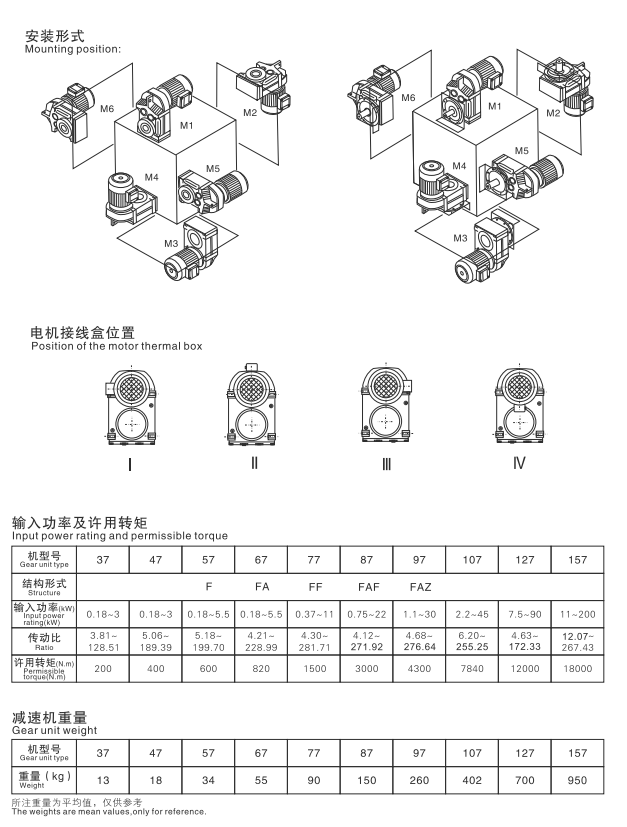

| Specification | FF107 |

|---|---|

| Input Power (kW) | 2.2 – 45 |

| Gear Ratio (i) | 6.20 – 255.25 |

| Output Torque (N·m) | 7,840 |

| Efficiency (%) | ≈96 |

| Gear Unit Weight (kg) | 402 |

| Structure Type | Parallel Shaft, Foot-Mounted |

The FF107 Parallel Shaft Helical Reducer is widely used in medium-to-heavy load continuous operation systems, where reliability and torque consistency are critical:

Belt & Chain Conveyor Systems – Long-distance material transport in logistics, mining, and cement plants.

Mixers & Agitators – Ensures high torque for mixing viscous materials in chemical and construction industries.

Lifting & Hoisting Equipment – Drives bucket elevators, winches, and chain lifting platforms.

Packaging & Palletizing Lines – Provides stable motion control in industrial packaging systems.

Metallurgy & Mining Machinery – Powers crushers, feeders, and screening systems.

Wastewater Treatment Plants – Operates aeration and sludge handling equipment under continuous load.

| Feature | F Series (FF107) | K Series | R Series |

|---|---|---|---|

| Output Direction | Parallel | Right-angle | Coaxial |

| Torque Capacity | Very High (7,840 N·m) | High (≤4,300 N·m) | Medium |

| Efficiency | ≈96% | ≈97% | ≈98% |

| Best For | Conveyors, Mixers, Elevators | Angular transmission | Compact machinery |

| Installation Space | Longer footprint | Compact | Minimal |

| Durability | Excellent | Excellent | Good |

Summary:

The F Series (FF107) excels when parallel alignment and high load capacity are required — offering superior durability, energy efficiency, and reliability compared with right-angle gearboxes.

| Application Condition | Recommended Configuration |

|---|---|

| Heavy continuous operation | Pair with high-efficiency IE3 motor and reinforced bearing support. |

| Long conveyor or horizontal layout | F Series parallel-shaft structure for direct alignment and reduced vibration. |

| Frequent start/stop cycles | Combine with inverter drive or braking motor. |

| High ambient temperature or dusty environment | Choose IP65 protection with heat-resistant lubricants. |

| Torque-demanding vertical lifts | Add reinforced output shaft and torque arm mounting. |

Q1: What is the main advantage of the F Series parallel shaft design?

A: It allows the motor and output shaft to stay in line, ideal for long conveyors and systems requiring direct, parallel drive alignment.

Q2: How much torque does the FF107 deliver?

A: Up to 7,840 N·m, supporting heavy-duty industrial applications.

Q3: What is the efficiency compared to worm gearboxes?

A: Helical gear engagement ensures ≈96% efficiency, significantly higher than worm drives (≈75%).

Q4: Can it be used for continuous operation?

A: Yes, FF107 is built for 24-hour operation with low maintenance and high thermal stability.

Q5: What mounting options are available?

A: Standard foot-mounted (FF type), flange-mounted (FA type), and shaft-mounted (FAF type) structures are available.

FF107 parallel shaft helical gear reducer delivers 7,840 N·m torque, 96% efficiency, and 2.2–45 kW power. Ideal for conveyors, mixers, and heavy-duty industrial machinery.

The F Series Parallel Shaft Helical Gear Reducer (Model FF107) is an industrial-grade drive unit engineered for heavy-duty conveying, mixing, and lifting applications.

Featuring a parallel shaft configuration, helical gear engagement, and high torque capacity, it ensures smooth power transmission with exceptional efficiency and durability.

With an input power range of 2.2–45 kW, output torque up to 7,840 N·m, and efficiency above 96%, the FF107 is the ideal choice for equipment requiring continuous, stable, and space-aligned power delivery.

High Torque Output (7,840 N·m)

Designed for heavy-duty mechanical systems demanding reliable, long-term torque performance.

Parallel Shaft Design

Ensures linear alignment between motor and driven equipment — perfect for long conveyor and material handling systems.

Wide Ratio Range (6.20–255.25)

Offers flexible speed adjustment to suit various industrial transmission requirements.

High Efficiency (≈96%)

Helical gear design reduces friction losses and provides smooth, energy-saving operation.

Strong & Rigid Construction

Heavy-duty cast iron housing with hardened alloy steel gears ensures excellent shock resistance.

Low Noise & Vibration

Precision-ground gears and optimized tooth profiles guarantee quiet, stable performance.

Easy Integration

Modular system supports IEC-standard motors, variable-frequency drives, and braking motors.

Reliable for Continuous Duty

Engineered for 24/7 operation under industrial environments with minimal maintenance needs.

| Specification | FF107 |

|---|---|

| Input Power (kW) | 2.2 – 45 |

| Gear Ratio (i) | 6.20 – 255.25 |

| Output Torque (N·m) | 7,840 |

| Efficiency (%) | ≈96 |

| Gear Unit Weight (kg) | 402 |

| Structure Type | Parallel Shaft, Foot-Mounted |

The FF107 Parallel Shaft Helical Reducer is widely used in medium-to-heavy load continuous operation systems, where reliability and torque consistency are critical:

Belt & Chain Conveyor Systems – Long-distance material transport in logistics, mining, and cement plants.

Mixers & Agitators – Ensures high torque for mixing viscous materials in chemical and construction industries.

Lifting & Hoisting Equipment – Drives bucket elevators, winches, and chain lifting platforms.

Packaging & Palletizing Lines – Provides stable motion control in industrial packaging systems.

Metallurgy & Mining Machinery – Powers crushers, feeders, and screening systems.

Wastewater Treatment Plants – Operates aeration and sludge handling equipment under continuous load.

| Feature | F Series (FF107) | K Series | R Series |

|---|---|---|---|

| Output Direction | Parallel | Right-angle | Coaxial |

| Torque Capacity | Very High (7,840 N·m) | High (≤4,300 N·m) | Medium |

| Efficiency | ≈96% | ≈97% | ≈98% |

| Best For | Conveyors, Mixers, Elevators | Angular transmission | Compact machinery |

| Installation Space | Longer footprint | Compact | Minimal |

| Durability | Excellent | Excellent | Good |

Summary:

The F Series (FF107) excels when parallel alignment and high load capacity are required — offering superior durability, energy efficiency, and reliability compared with right-angle gearboxes.

| Application Condition | Recommended Configuration |

|---|---|

| Heavy continuous operation | Pair with high-efficiency IE3 motor and reinforced bearing support. |

| Long conveyor or horizontal layout | F Series parallel-shaft structure for direct alignment and reduced vibration. |

| Frequent start/stop cycles | Combine with inverter drive or braking motor. |

| High ambient temperature or dusty environment | Choose IP65 protection with heat-resistant lubricants. |

| Torque-demanding vertical lifts | Add reinforced output shaft and torque arm mounting. |

Q1: What is the main advantage of the F Series parallel shaft design?

A: It allows the motor and output shaft to stay in line, ideal for long conveyors and systems requiring direct, parallel drive alignment.

Q2: How much torque does the FF107 deliver?

A: Up to 7,840 N·m, supporting heavy-duty industrial applications.

Q3: What is the efficiency compared to worm gearboxes?

A: Helical gear engagement ensures ≈96% efficiency, significantly higher than worm drives (≈75%).

Q4: Can it be used for continuous operation?

A: Yes, FF107 is built for 24-hour operation with low maintenance and high thermal stability.

Q5: What mounting options are available?

A: Standard foot-mounted (FF type), flange-mounted (FA type), and shaft-mounted (FAF type) structures are available.

FF107 parallel shaft helical gear reducer delivers 7,840 N·m torque, 96% efficiency, and 2.2–45 kW power. Ideal for conveyors, mixers, and heavy-duty industrial machinery.